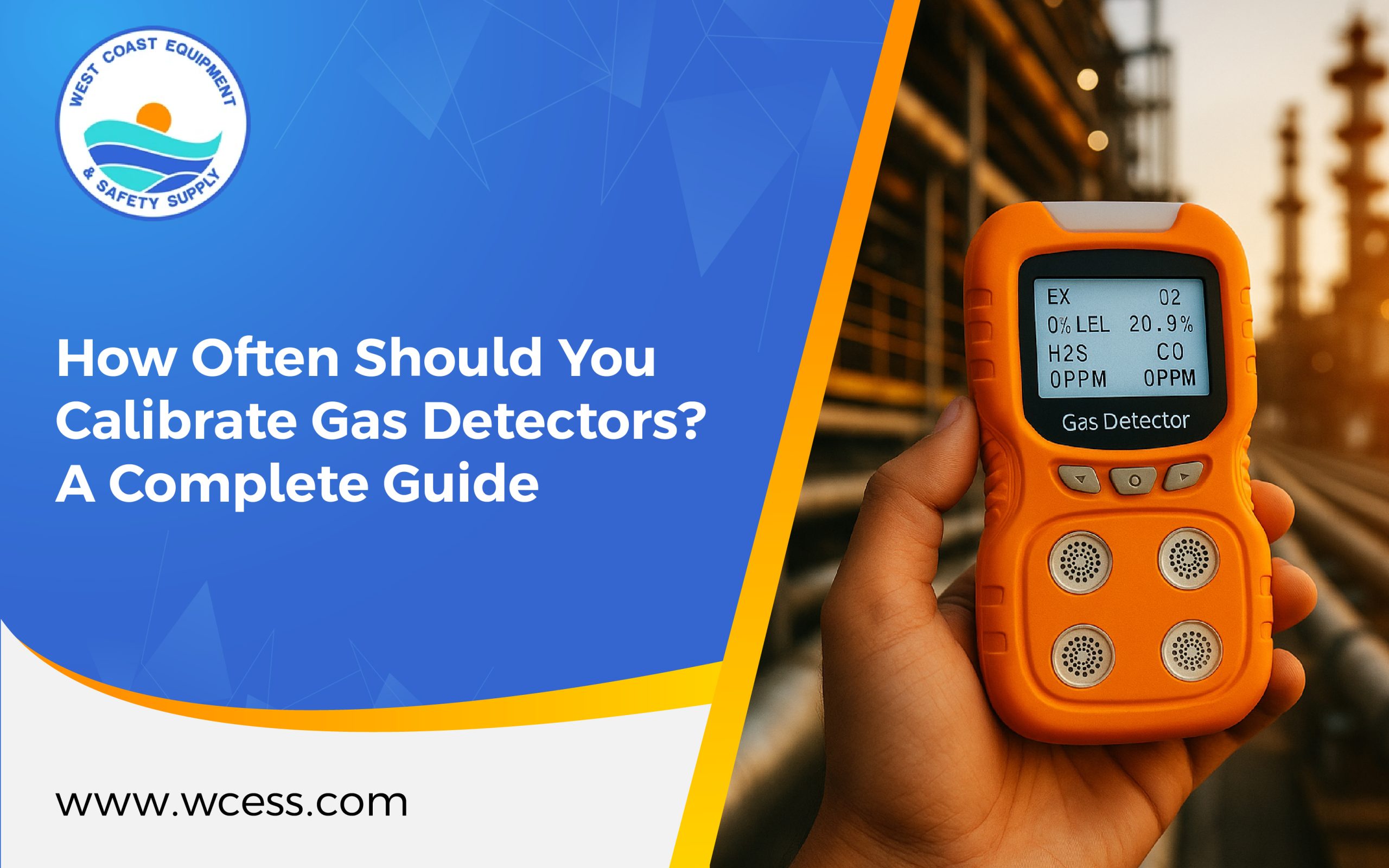

Safety is not a switch that can be turned on and off at will. It is constant, ever-present as the air we breathe. Gas detection is about more than compliance. It’s critical safety infrastructure and the first line of defense against unbreathable air. Regular gas detector calibration reflects a respect for human life in your workspace.

In every industrial, commercial, and laboratory environment, early Hazardous gas monitoring is the only defense against all dangers. A well-calibrated detector identifies hazardous gases before they reach dangerous levels. But owning a gas detector isn’t enough. Calibrating it for accuracy is the most accurate measure of responsibility.

Don’t Wait for Alarms to Fail

Calibration is the process of addressing problems before they grow roots. It’s done by testing the gas detector’s sensor against a known concentration of a test gas. Based on the reading, the sensor is adjusted to maximum accuracy.

Environmental exposure, temperature changes, or regular wear and tear affect the accuracy of the sensor. Aware of this danger, OSHA laws mandate gas monitor calibration to stay ahead of the risk of hazardous gas exposure, delays in detection, and response.

Gas detectors measure gas concentrations and trigger alarms when concentrations reach high levels. If calibration is not done regularly, it can lead to:

- False alarms

- Missed alarms

- Noncompliance with occupational safety regulations

- Reduced trust in safety equipment

- High maintenance costs

Business owners who value life don’t wait for gas detection systems to fail; they calibrate them. They don’t wait for alarms to sound before paying attention to the sensor’s integrity. Out of respect for their employees, they calibrate to keep their guard up.

Safety Starts With Informed Planning

It’s recommended to engage gas detection calibration services practitioners for informed counsel on calibration frequency, tailored to your business environment and needs. The type of detector and frequency of use also determine the frequency of calibration.

However, here are standard guidelines:

- Bump test (function check): Before each day of use or shift, depending on the sensor and alarms, respond to the presence of gas.

- Full calibration: Every 30 to 180 days (1-6 months) to calibrate the sensor output to match a known gas concentration.

- Post-service calibration: After sensor replacement, battery change, or exposure to contaminants, ensure sensor accuracy is restored.

Factors Affecting the Frequency of Calibration

The following conditions may force you to schedule more frequent calibration:

- Harsh environments, including high-humidity areas

- Continuous exposure to target gas or chemicals

- Portable gas detectors exposed to changing environments

- Detectors used in critical safety operations, such as confined spaces

- Low-risk gas monitor use

Regulatory and Manufacturer Recommendations

Organizational safety and health standards recommend following the manufacturer’s specifications for gas monitor calibration. Doing this will also preserve the manufacturer’s warranty. Replace the sensors when calibration fails repeatedly to maintain the warranty.

Manufacturers recommend scheduling calibration at intervals of six months to maintain warranty and certification validity. Safety regulations require businesses to maintain an up-to-date safety record, along with calibration logs, as proof of regular maintenance.

During calibration, ensure the use of certified calibration gases with known concentrations for accurate results. If calibration is performed daily, ensure personnel responsible are trained and certified for bump testing and calibration procedures.

Calibration Dates Expire

Never let complacency dull vigilance. Schedule frequent calibrations to ensure accurate readings, comply with calibration gas standards, and provide peace of mind for every worker and visitor on site.

Detector calibration should not be left to chance. Professional gas detection calibration services ensure that every reading is verifiable and documented for safety compliance and certification purposes.

Reject the Idea That Once is Enough

Safety is not a one-time effort, it is a commitment renewed every single day. Gas detectors may be the silent guardians of your workspace, but their reliability depends entirely on how seriously you take calibration. Every accurate reading is a promise of protection. Every calibration is an act of responsibility.

At West Coast Equipment & Safety Supply, we ensure your detectors do more than beep, they protect with precision. Our professional calibration services restore accuracy, validate compliance, and secure the confidence your team deserves.

Schedule your gas detector calibration with West Coast Equipment & Safety Supply today!